ABOUT US

Shandong Guancounty Meian Composite Materials Co., Ltd.

Shandong Guanxian Meian Composite Materials Co., Ltd. was established in 2017 and is a high-tech enterprise specializing in the full-chain industry of prefabricated buildings and green building materials.

The company is located in the Guanxian Industrial Park, Shandong, covering an area of 230 acres, with over 300 employees. After rapid development, Meian Building Materials has formed five core business sectors: prefabricated building modules, prefabricated building molds, prefabricated decoration materials, rural housing solutions, and ultra-strong steel pipe support building modules. Its products are widely involved in various fields and have successfully become a “National Green Building Materials Rural Promotion Enterprise.”

With outstanding technical strength and product quality, Meian Building Materials has gained high recognition in the industry and obtained important qualifications and honors, including: Shandong Provincial Prefabricated Building Industrial Base, Provincial “Specialized, Refined, Novel, and Unique” Enterprise, Shandong Provincial “Gazelle” Enterprise, Provincial Smart Manufacturing Typical Enterprise, Shandong Provincial Manufacturing Industry Single Champion Enterprise, Shandong Provincial Quality Benchmark Enterprise, Shandong Provincial Manufacturing Brand Certification Enterprise, Shandong Provincial High-End Brand Cultivation Enterprise, and Shandong Provincial Intellectual Property Advantage Enterprise.

It is also a leading enterprise in Shandong Province’s Prefabricated Building Parts and Components Industry, a member of Shandong Province’s “Top 10” Industrial Cluster Enterprises, and a Green Building Materials Product 3-Star Certification Enterprise.

The company places a high value on technological innovation, having established the Shandong Provincial Postdoctoral Innovation Practice Base and the Shandong Provincial Enterprise Technology Center, among other provincial innovation platforms. Currently, the company holds 46 patents and actively participates in the formulation of industry standards, having contributed to the development of four group standards and four local standards. Meian has close cooperation with universities and research institutes such as Jinan University and Shandong Jianzhu University, providing a solid technical foundation for its continuous development.

Meian Building Materials’ products are reliable in quality and widely applied. The products successfully cover the procurement catalog for bulk building materials in the Xiong’an New Area (thermal insulation system materials) and have been evaluated for landmark projects such as the Xiong’an New Area Business Service Center, Xi’an International Airport, Liaocheng University Engineering Technology and Modern Agriculture Industry-Academia Integration Project, and Beijing Tongji Daxing Incident Project. The company’s market territory continues to expand, with products exported to over ten countries and regions, including Russia, Kazakhstan, Canada, and South Korea.

Meian Building Materials is committed to continuous value exploration and innovation, creating better working conditions for construction workers and contractors, promoting the sustainable development of the construction industry, and contributing to the advancement of China’s green building materials industry with “Meian Power.”

1. Technological Advantage

The company has gained recognition as a National High-tech Enterprise, Shandong Province “Gazelle” Enterprise, Manufacturing Industry Single Champion, Quality Benchmark Enterprise, “Specialized, Refined, Novel, and Unique” Enterprise, and the Leading Enterprise in the “Top 10” Industry Cluster, among other 12 provincial and national authoritative certifications. The company has also earned the evaluation as the Shandong Provincial Prefabricated Building Industry Base and Green Building Materials 3-Star Certification. With the establishment of Shandong Province’s Postdoctoral Innovation Practice Base and Enterprise Technology Center, along with other provincial-level innovation platforms, Meian Building Materials owns 46 patents and actively participates in industry standard development, leading or co-authoring 4 local standards. The company maintains close cooperation with universities and research institutions such as Jinan University and Shandong Jianzhu University, providing strong support for product research and technological advancement, solidifying its position as a technology leader in the industry.

2. Product Advantage

Meian Building Materials produces asbestos-free fiber cement boards/calcium silicate boards from carefully selected imported raw materials. The production process includes automated pulp preparation, precision molding, 7,000-ton high-pressure pressing, and high-temperature steam curing. The products are characterized by high density, strong strength, and stable performance, meeting various customer requirements for board performance and specifications. They also feature outstanding functional properties, using an asbestos-free, environmentally friendly formula, lightweight, and high-strength advantages. Additionally, they provide Class A fire resistance, water resistance, freeze resistance, weather resistance, low water absorption, anti-sagging, non-deformation, and are suitable for various harsh environments, with a long service life. These products are widely used in construction exterior wall systems (e.g., insulation decorative unit panels, exterior wall hanging panels), interior decoration systems (walls, ceilings), and industrial and prefabricated buildings (coated substrates, prefabricated components, etc.).

3. Production Capacity Advantage

Meian Building Materials has a modern production base equipped with comprehensive information technology. The company has already launched three customized fiber cement board/calcium silicate board production lines, with an annual output of 15 million square meters. It also operates eight coating single-panel production lines with an annual output of 3 million square meters and five integrated insulation decorative board production lines, with an annual output of 1.5 million square meters. Thanks to a highly automated and information-driven production system, Meian Building Materials can achieve large-scale customized production, with the maximum panel size reaching 1220*3000 mm, ensuring reliable product quality at different thicknesses. Additionally, the company provides one-stop product and system solutions, meeting diverse needs.

Shanghai Elue Devlopment Histroy

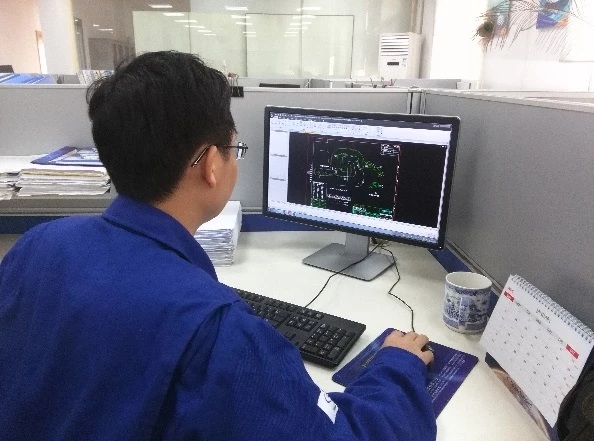

Upgrading our facilities as per the latest technological advancements has been the priority in our manufacturing philosophy. These years, we are proud to follow the best manufacturing practices and stringent quality control checks.

2021

We imported 10 more sets automatic lathes which gave us a big advantages on those small parts to lower costs and won a lot of business and we set up a new facility.

2018

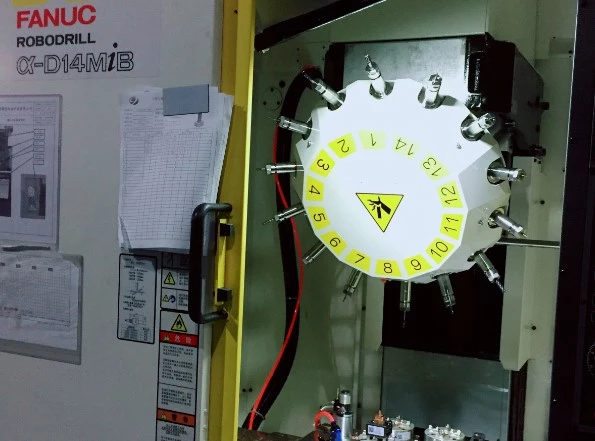

We employed 60 members with various machines available to provide customers one-stop CNC service, also we imported 8sets more Fanuc machining centers.

2015

To meet the high expectations from the customers, our QC room was equipped with complete inspection instruments, like CMM, Projectors, Hardness tester, Roughness tester,and more.

2012

We started to work with those big brands because of our reputation and consistant quality standards.

2009

We started to export to USA and gained some stable business, to guarantee the first-class service, we employed english-speaking engineers.

2006

Our boss resigned from a Japan manufacturing company and started this CNC machining business from several ordinary milling machines and lathes.

Our Factory

YOU ARE CURRENTLY FACING the Offshore PURCHASING Challenges ?

WHAT WE CAN HELP YOU

Why Choose Us

Communication Skills

Our sales team can speak and write fluent English, also they have a good knowledge of machining technics, Easy to talk.

Fast Response

All your rfqs and questions will be replied within 12hours, and your own project manager can be available 7days per week.

Fast Delivery

We can make your parts as fast as 2days. our current orders always ship out 3-5 days before due-date.

Well-equpped Facility

With the most advanced equipment in house, we can provide high tolerence parts ±. 0.002mm and one-stop service.

Quality Guarantee

Commitment to delivering precision parts with mature quality management system including IATF16949 certifications.

NO-MOQ

e accept both prototyping and mass production jobs, it means that we can support you during this whole process.

Plastic Molding Projects

Shanghai Elue is an expert to provide plastic mold injection service. Over the years,we have run various plastic molds for different industries.

CNC Machining

The majority have suffered alteration in some form, by injected humor, words which don’t look even slightly.

Plastic Molding

The majority have suffered alteration in some form, by injected humor, words which don’t look even slightly.

Aluminum Extrusion

The majority have suffered alteration in some form, by injected humor, words which don’t look even slightly.